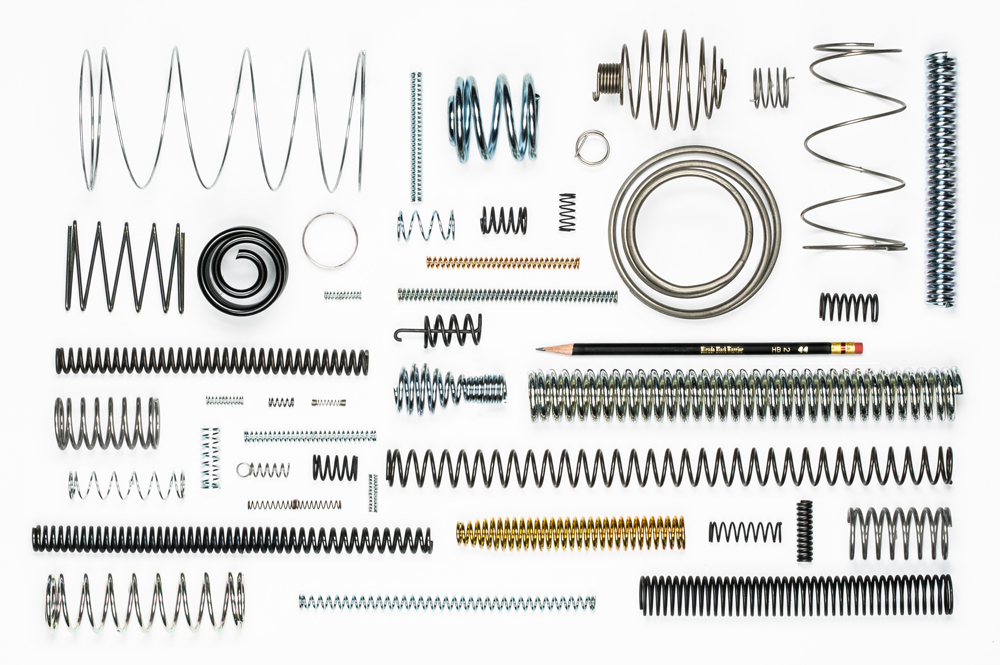

Mid To High Volume Compression Springs Are Skillfully Manufactured and Delivered On-time

Compression springs are used to resist applied forces or to use its energy in the push action. With compression springs, wide load and deflection range can be achieved. They can have a constant or variable rate achieved. The customary material used is round wire and the prevalent shape is the straight cylindrical.

- Helical compression springs are used to resist compression or to store energy to push.

- There are conical, barrel, hourglass, or straight conical.

- Compression springs can be made with or without variable spacing between coils.

Compression Springs Specifications

The Patrick Manufacturing team is available to consult on compression spring designs for high volume production needs and applications.

Custom Compression Spring ShapesPatrick Manufacturing produces custom compression springs in a variety of shapes and configurations to industry standards and tolerances.

| Compression Spring EndsIn addition to providing, custom compression shapes, Patrick Manufacturing provides custom ends including:

|

Not seeing what you’re looking for? Contact us today to learn about our various compression spring capabilities.

Featured is a straight constant pitch compression spring with closed ends and no grind. Made from .067 music wire with a free length of 1.25". Typical application in the material handling industry. EAU: 250,000

At Patrick Manufacturing, we proudly produce compression springs on state-of-the-art CNC spring coilers. We manufacturer to your exact design specifications such as:

- Free Lengths

- Solid Height

- ID / OD

- Wire Diameter

- Number of Coils

- Pitch (variable and constant)

- Spring Rate

Contact Us today to learn about more about our custom capabilities we specialize in!